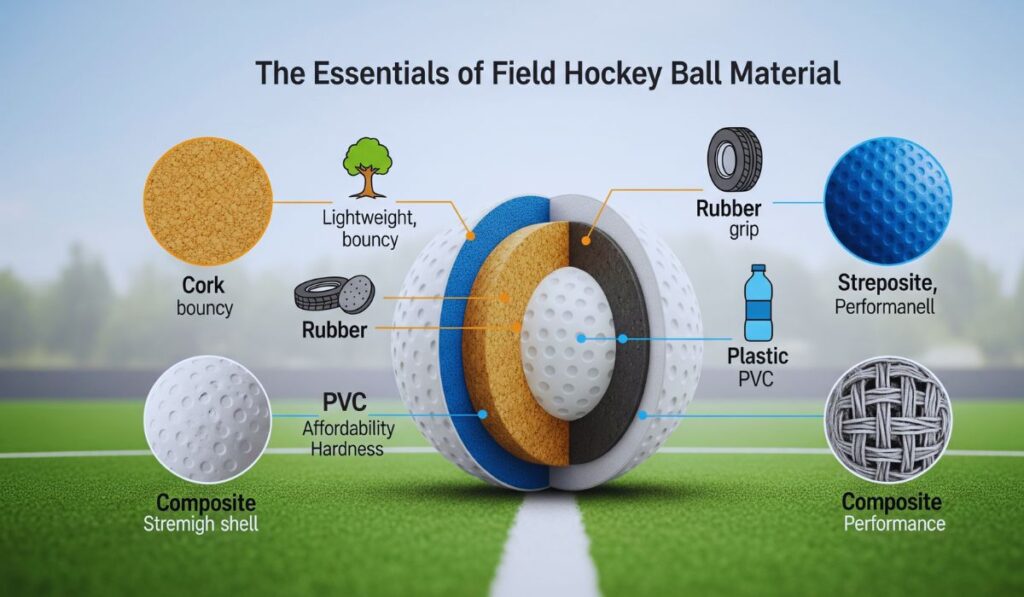

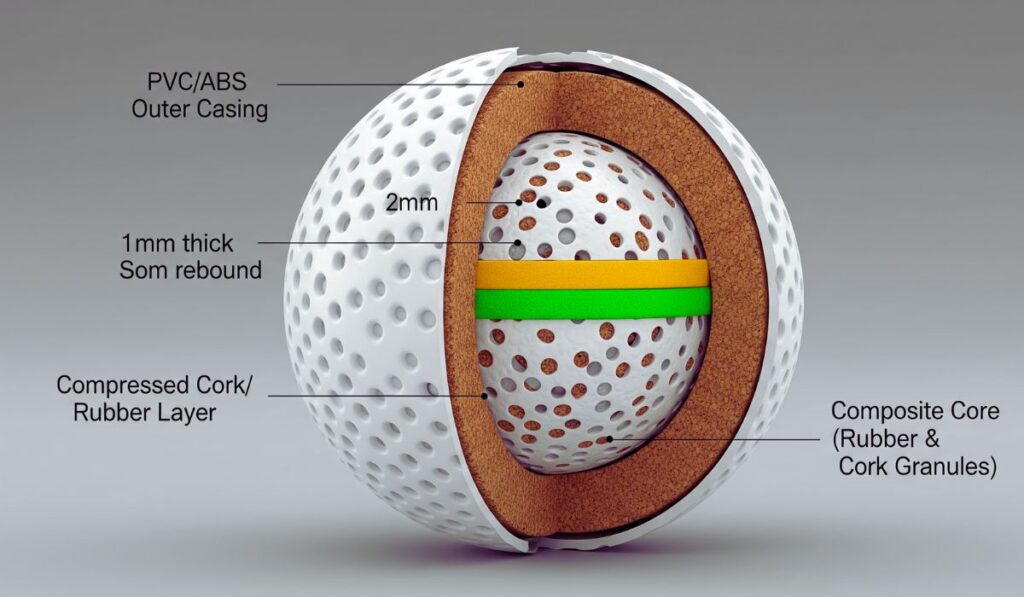

Most field hockey balls today are crafted from a solid-body plastic shell—typically polyvinyl chloride (PVC) or high-density polyethylene (HDPE)—with an optional core of cork, rubber, or wood. This combination offers remarkable durability and consistency. The material must meet strict standards: a circumference of 224–235 mm and a weight of 156–163 g in line with FIH regulations . That tight tolerance means every strike feels predictable—essential in high-speed play.

Why Cork Cores Still Matter

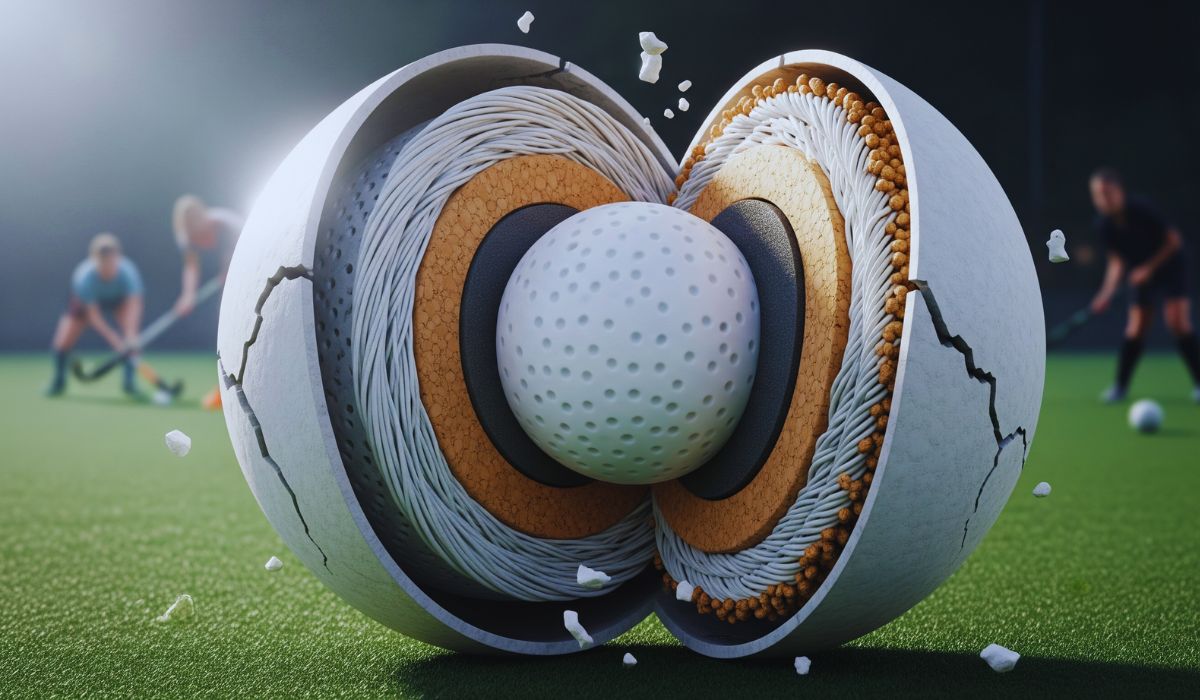

While pure plastic balls are common, many top-level models include a cork core beneath the shell. That inner layer may be made of cork or compressed composite material. It adds shock absorption, steadies the weight distribution, and delivers a satisfying, consistent ball feel when the stick connects. This hybrid design enhances control and rebound predictability on turf, especially during slowing or wet conditions.

The Role of Dimples in Aerodynamics and Speed

Most elite field hockey balls feature a dimpled surface, similar to a golf ball. These dimples help reduce friction on wet or damp turf, prevent aquaplaning, and promote a smooth, fast roll across the surface. Dimples also create micro‑air pockets that reduce drag, enabling speeds of up to 145 km/h Visually, a dimpled texture provides a tactile confidence that conveys control before the ball even leaves the stick.

Smooth vs. Dimpled: Surface Choices for Different Uses

Not all field hockey balls are dimpled. Smooth‑surfaced balls are preferred for indoor use or training on grass, where dimples might disrupt consistency and bounce. Hollow practice balls—lighter and often colored—are used for beginners or casual drills. They provide softer impact and extra safety, sacrificing tournament‑level speed in exchange for ease and visibility

Material Durability and Resistance to Impact

The plastic shell of a regulation ball must resist frequent high‑velocity hits without cracking or distorting. PVC and HDPE offer toughness and weather resilience. Consistent density throughout prevents warping, and any fillers or quality-controlled molding processes eliminate weak spots. That durability directly impacts how long the ball retains its shape, weight, and aerodynamic behavior beneath repeated impacts.

Weight Uniformity: The Secret to Fair and Consistent Play

Uniform weight is not a luxury—it’s a necessity. Every ball must stay within the 156–163 g range so players can anticipate bounce, release, and ball speed. That consistency depends on material density and quality control during production. A ball that’s too light—or too heavy—upsets timing, shot rhythm, and fairness. High-end models use high-precision molds and consistent raw materials to avoid such variances I

Color Choices: Visibility Meets Regulation

While white remains the most common field hockey ball color, other high‑visibility hues like orange or yellow are widely accepted—especially under changing lighting conditions or on surfaces that render white indistinct. FIH rules mandate that the ball’s color must sharply contrast with the playing surface. So, the material must also support vibrant, fade‑resistant pigment applications, keeping the ball visible under artificial lighting and across different fields

Why Ball Material Still Shapes the Game

Understanding field hockey ball material matters because it defines the way the game feels and plays. A ball made from inconsistent plastic or with voids in the core will bounce unpredictably, leading to errant passes, misreads, and fractured confidence. The combination of solid, weather‑proof plastic, controlled weight, balanced rebound, and strategic dimpling shapes the tempo of play and the precision of technique. In contrast, training with inferior balls dulls timing and touch—a risk few serious players can afford.

The Feel of the Ball: Sensory Feedback and Touch

Ask any seasoned player, and they’ll tell you: not all field hockey balls “feel” the same. The moment a stick connects with the ball, you get a subtle but crucial vibration—a kind of tactile signal—that tells you how cleanly it was struck. That sensory feedback is shaped entirely by the material. Premium balls deliver a solid, crisp contact with minimal wobble. Inferior materials, by contrast, feel hollow, overly bouncy, or dead. That’s why material quality isn’t just about strength; it’s about feel, control, and the confidence to execute precision passes under pressure.

Environmental Factors: Heat, Cold, and Surface Interactions

A hockey ball made of poor plastic will warp or harden under temperature shifts, creating unpredictable bounce or drag. PVC and HDPE are chosen for their ability to withstand both summer heat and winter frost. Even in sub-zero climates, a well-made ball retains elasticity and shape. Additionally, wet fields test the ball’s ability to grip or skim the surface. Material science here makes or breaks performance—cheap balls slide out, while top-tier ones maintain predictable roll and friction regardless of turf conditions.

Training Balls vs. Match Balls: Not Just a Price Difference

A common misconception is that all hockey balls are interchangeable, but players quickly learn the difference. Training balls are often hollow or semi-solid, lighter, and sometimes made of recycled plastic. These are fine for developing muscle memory or repetitive drills but aren’t suitable for match-level play. Match balls use denser materials with consistent inner cores and calibrated weight. Practicing exclusively with low-quality balls can cause a false sense of timing, leading to mistakes in real-game scenarios.

The Hidden Science of Impact Resistance

A field hockey ball needs to survive over 100 km/h hits, deflections, and turf abrasion repeatedly. Manufacturers test for impact resistance using advanced machinery that mimics game scenarios. The shell must not crack, flake, or warp. It’s not just about surviving a strike—it’s about withstanding thousands of them over time. The inner materials must flex slightly under load but return to original form instantly. This careful balance of strength and elasticity is where advanced polymers like HDPE outperform traditional materials.

Noise Matters: Acoustics of a Great Hit

It may sound odd, but the sound a hockey ball makes when struck reveals a lot about its quality. A good ball offers a sharp, snappy “clack” when hit cleanly. A dull thud often indicates compromised density or cheap inner materials. During elite play, players rely on these subtle audio cues to sense the strength and accuracy of their pass or shot. This is especially true in tight matches where sensory overload is high—every sound counts. And the material of the ball is what shapes that acoustic profile.

Branding and Price: Does Material Justify the Cost?

Brands like Grays, Kookaburra, and TK charge more because they invest heavily in material selection, testing, and batch consistency. Cheaper alternatives may look identical on the shelf but lack the internal structure that separates amateur gear from pro-level equipment. That said, some mid-range balls offer surprising quality if the materials are correctly blended. Players should look for FIH-approved marks or verified match-grade materials when choosing a ball. Price often reflects hidden quality—not just the logo.

Field Type Influences Material Performance

Not every ball behaves the same on every surface. Water-based turf, sand-dressed turf, and dry grass all react differently to the same ball. That’s why understanding material behavior on different surfaces is crucial. Dimpled balls, for example, excel on water-based turf by reducing hydroplaning. Smooth-surface balls are better suited to sand or indoor courts. A versatile material should maintain its bounce, friction, and velocity across all three. This is why FIH-standard balls use highly calibrated plastics.

Color Fading and Pigment Stability

Vibrant colors aren’t just about aesthetics—they’re about long-term performance. A ball that loses its color becomes difficult to track visually, especially during fast play. UV exposure, turf chemicals, and frequent washing can cause colors to fade if poor-quality pigments are used. High-grade balls are infused with UV-resistant pigment during manufacturing, not just coated on the outside. This material-based approach ensures that even after 100 matches, the color—and performance—remain intact.

Maintenance and Material Compatibility

Cleaning your hockey ball regularly extends its lifespan, but only if you know what it’s made of. Cheap plastic may react poorly to detergents or alcohol-based cleaners, cracking or weakening over time. Premium materials are resistant to cleaning agents, turf grime, and even bacteria buildup. Cork-core balls can absorb moisture if left in water, while fully sealed balls resist internal waterlogging. Knowing the ball’s material helps players treat and store it correctly, protecting their investment.

Material Evolution: From Leather to Polymer

The earliest hockey balls were stitched leather stuffed with cork or sawdust—great for nostalgia, but a nightmare in wet conditions. As the sport evolved, so did the materials. Leather gave way to rubber, then synthetic polymers in the late 20th century. Today, high-density plastics and composite blends dominate, offering speed, durability, and weather resistance unimaginable in the past. Understanding this material journey deepens appreciation for how far the sport—and its equipment—have come.

The Psychology of a “Trusted” Ball

Every player has that one hockey ball they instinctively reach for—the one that “feels right.” That psychological trust isn’t arbitrary. It’s built over hours of consistent performance. When a ball’s material delivers predictable bounce, sound, and response time after time, the player builds subconscious confidence. That trust becomes crucial in high-pressure moments. This is why consistent material manufacturing and quality control matter. A trusted ball isn’t just a tool—it’s a psychological edge.

Material Fatigue: When to Retire a Ball

Even the best-made ball has a lifespan. Over time, plastic wears down, internal cork compresses, and bounce subtly decreases. A tired ball may still look clean but feel slightly “dead” on impact. Players often miss these micro-changes until their timing is off during games. Knowing the signs of material fatigue—flattened dimples, inconsistent bounce, softened shell—is key to retiring old gear at the right time. Investing in fresh, high-quality balls keeps your game sharp.

The Impact of Manufacturing Techniques

Two balls can use the same material and still behave differently depending on how they’re made. Compression molding, rotational molding, and injection molding each influence the density, shape, and internal structure. Top-tier balls use precision molds that ensure even distribution of material, with zero air pockets or weak zones. Budget balls often cut corners here, leading to warped shapes and inconsistent weight. That’s why understanding not just what the ball is made of—but how it’s made—is so important.

Regulation and Approval Standards

The FIH (International Hockey Federation) sets strict guidelines for field hockey balls, including bounce height, circumference, weight, and rebound consistency. To meet these standards, ball manufacturers must use materials that can pass repeated testing under controlled conditions. These certifications ensure that the ball behaves the same in India, the Netherlands, or Australia—regardless of climate. As such, approved materials must resist swelling, warping, or degradation even in humid, wet, or dry environments.

The Emotional Pull of Premium Gear

There’s something deeply satisfying about unboxing a new match ball—shiny, clean, perfectly round. It taps into the emotional joy of anticipation and high standards. That first perfect pass, the satisfying sound of a clean strike—these sensory moments stick with players. That emotional pull is no accident. Brands craft not just physical objects but experiences. Premium material creates that emotional “wow” factor that lingers. And players who feel good, play better.

Understanding the Core Composition of Field Hockey Balls

The heart of every field hockey ball lies in its core composition. This central part often determines how the ball behaves on the field—how it bounces, rolls, and responds to contact with the stick. Most modern field hockey balls use a cork or rubber core, encased in a hard plastic shell. The cork gives the ball a slightly softer touch, making it easier to control, especially in dribbling or receiving fast passes. Rubber-core balls, on the other hand, offer more resilience and tend to last longer on synthetic pitches. Understanding what lies inside a field hockey ball allows players to choose gear that complements their playing style and surface preference.

Why Outer Shell Material Matters More Than You Think

The outer shell of a field hockey ball plays a crucial role in the way the ball interacts with both the stick and the playing surface. This shell is typically made from PVC or hardened polyurethane. PVC provides a solid, rigid surface that holds up under intense matches and remains consistent in performance. Polyurethane, on the other hand, is slightly more flexible, making it ideal for turf play where grip and rolling speed matter. These material choices may seem subtle, but they significantly impact game flow and control, especially at competitive levels.

The Sensory Feel of Different Field Hockey Ball Materials

Players often underestimate the sensory experience of field hockey. The material of the ball influences not just performance but also the tactile feedback felt through the stick. A ball with a polyurethane shell may give a slightly softer “feel” upon contact, making trapping and dribbling smoother. In contrast, a PVC shell offers a crisp, clean hit and louder acoustics—an advantage for players who rely on auditory cues. These small differences can shape a player’s perception of ball control and confidence during matches.

How Material Impacts Durability on Different Playing Surfaces

Not all field hockey balls are created equal, especially when it comes to durability. Balls used on water-based turfs typically endure less wear, so softer materials like cork or composite blends can suffice. However, on harder grass or sand-filled turf, tougher shells made from PVC are essential to withstand constant abrasion. Repeated impact with a coarse surface can degrade lower-quality materials quickly, leading to cracks, uneven rolling, and performance decline. That’s why choosing the right field hockey ball material based on your surface is vital for longevity.

Temperature Effects on Field Hockey Ball Performance

Many players don’t realize how temperature affects the materials used in field hockey balls. In colder climates, balls made with harder materials like PVC can become too rigid, making them bounce unpredictably and feel unpleasant to hit. Meanwhile, balls with rubber or mixed-core materials maintain better elasticity and control. On hot days, soft material balls might deform slightly under pressure, reducing accuracy. Knowing how your environment influences the ball’s material behavior can be the key to adjusting your gameplay accordingly.

The Role of Dimple Patterns and Material Bonding

One often overlooked aspect of field hockey balls is the dimple pattern on the surface. These dimples help maintain a consistent trajectory, especially on wet fields. The material must bond seamlessly with the dimpled design to ensure that water dispersion doesn’t disrupt the ball’s flight or spin. In well-crafted balls, the plastic or composite shell integrates tightly with the pattern, preventing dirt buildup and ensuring smooth rolling. Players looking for precision and speed should always examine the texture and how well the material supports it.

Price vs. Performance: When Material Dictates Value

Field hockey ball material significantly impacts the pricing of the product. Entry-level balls made from basic PVC and foam cores may be affordable but offer limited game realism and durability. Mid-range balls blend rubber, cork, and PVC, offering a balanced experience for training and amateur matches. Top-tier balls use refined materials that are pressure-tested, seam-welded, and responsive—ideal for competitive play. While it’s tempting to save money, choosing better materials usually translates to better consistency, fewer replacements, and a more satisfying experience on the field.

Evolving Innovations in Field Hockey Ball Material

Technology in sports gear doesn’t stop, and field hockey is no exception. In recent years, manufacturers have experimented with eco-friendly materials that reduce plastic use while maintaining professional-grade performance. Bioplastics, recycled rubbers, and even sustainable foams are entering the market, offering players and coaches greener alternatives without sacrificing control or speed. These innovations not only improve gameplay but also speak to the changing values in sports—where material selection considers both performance and planet.

Final Thoughts: Why Material Isn’t Just a Detail

In the world of field hockey, success comes down to millimeters and milliseconds. The quality of your ball’s material affects every aspect of your game—speed, control, confidence, even safety. Investing in a well-made ball isn’t a luxury. It’s a necessity for serious players and passionate beginners alike. When the material is wrong, the game feels off. When it’s right, everything flows. That’s the power of choosing the right material—for your team, your skills, and your performance.

1 thought on “The Essentials of Field Hockey Ball Material”